Is forklift damage costing you money?

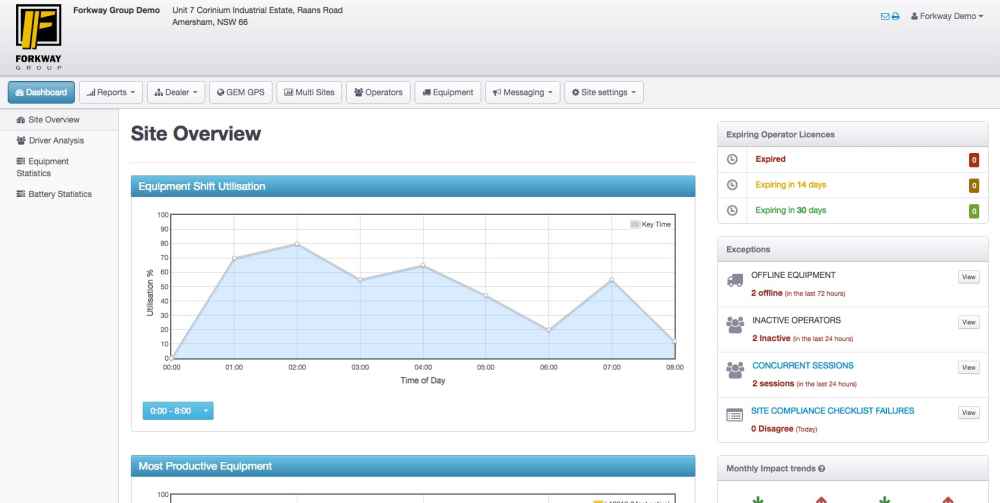

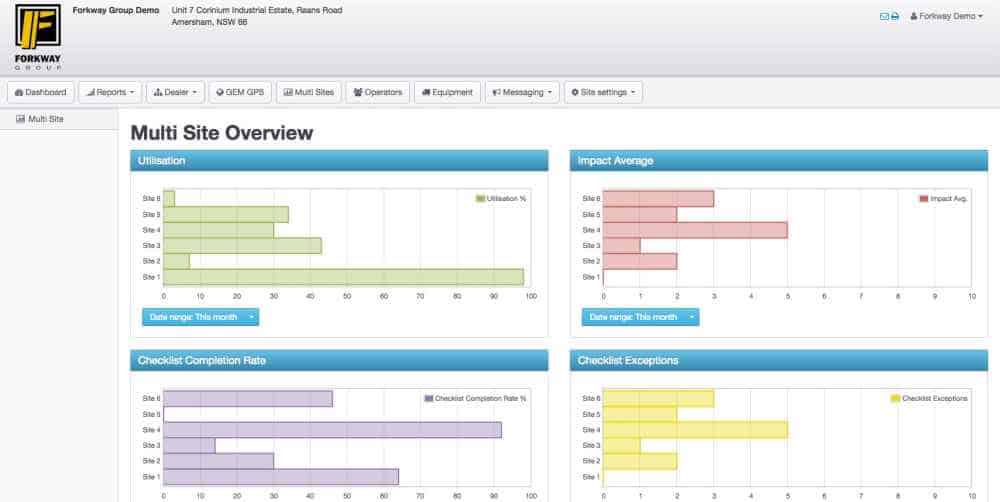

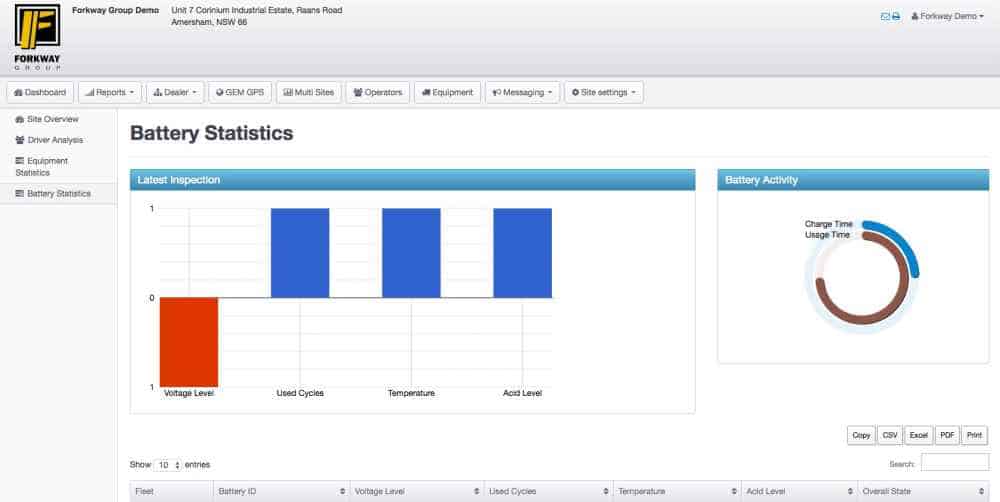

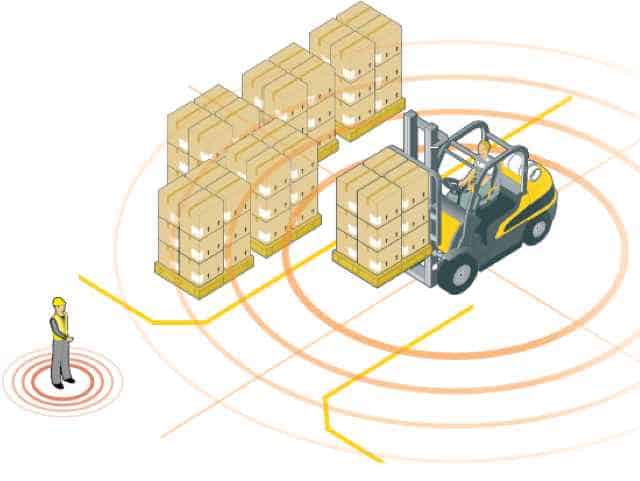

From less than £1 a day Forkway Fleetsafe can minimise the cost of forklift damage. The Forkway Group is now proud to present to the UK Market four innovative solutions referred to as FleetSafe, ZoneSafe, ReverseSafe and SpeedZone. Combined under the banner of FleetSafe, Forkway are offering the ultimate intelligent telemetry system, providing fast clean data that enables companies to take immediate and corrective action. The system can be tailored to specific requirements with customised reports and additional features, ensuring you receive the information and support that is of most value to your business.

The innovative FleetSafe system is fully adaptable to suit individual needs and customers are able to choose specific features of the four systems to include in their package, ensuring they receive the results that are essential to improving their warehouse operations. The main features available across the four systems include a forklift mounted LCD control unit, online management, collision alerts, speed limiting abilities, pedestrian detection and motion sensors.

Designed by experts, chosen by professionals, used by our customers, Forkway FleetSafe can and will limit costs, maximise productivity and provide the safest possible working environment for you and your team from less than a £1 a day.