Established in 1988, Simpson Packaging is one of the UK’s leading suppliers of packaging materials, handling equipment and workwear to the removals, self-storage and furniture industries as well as being a major force in industrial packaging. The continuing success is due to one major factor: putting the customer first, so when your existing warehouse starts to impact on your operational efficiency, it’s time to move!

In October 2016, Simpson Packaging moved into a new 33,000 ft² purpose-built warehouse that is more than three times the floor area, nearly twice the height, has an additional 8000 ft² two-tier mezzanine floor and three times the office accommodation.

One of the initial benefits of having more space was the ability to be able to order from suppliers in much larger volumes, thereby keeping costs down for their existing customers but also now being able to cater for a significant increase in new business. It was soon obvious however, that even more pallet locations were going to be needed.

3 NEW AISLE-MASTER FORKLIFTS

INCREASE OF 1200 PALLET LOCATIONS

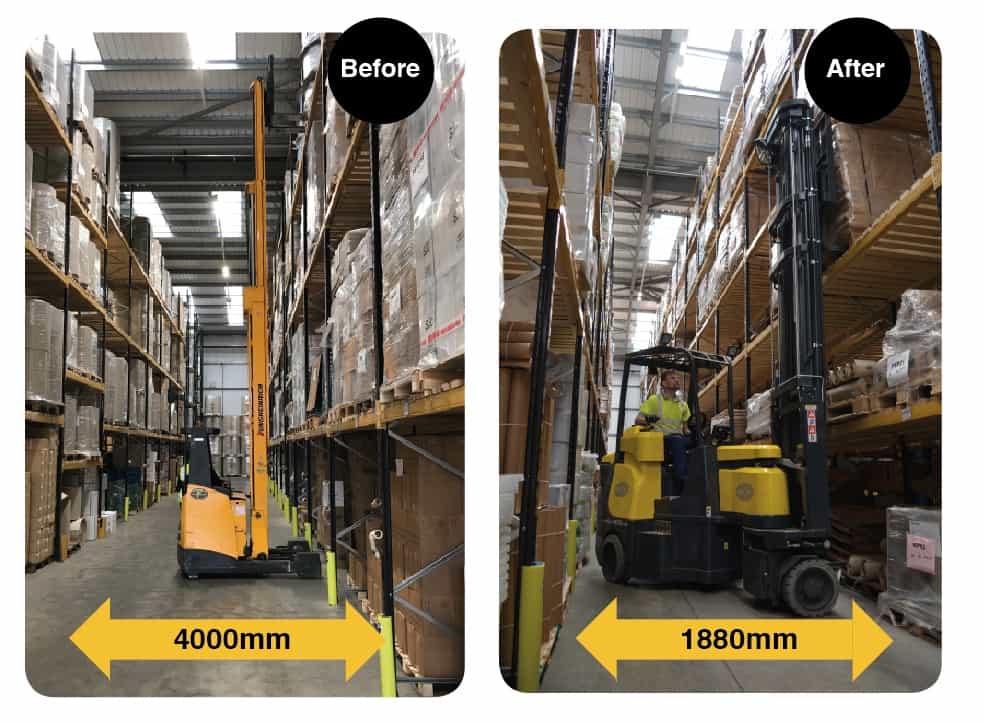

AISLES REDUCED FROM 4000MM TO 1800MM

“Simpson Packaging had been using a mix of Reach Trucks and Electric Counterbalance Trucks for a number of years,” commented Forkway Group Director, Richard Greaves. “They needed the flexibility to store different products and pallet sizes so decided on an initial racking install that would create 4000mm aisles with a view in future to add in a second phase to reduce the widths to create narrow aisles. However the extra pallet locations they initially gained from the move were soon taken up by additional stock, so we were called in to look at what options were available in order to increase storage capacity, whilst at the same time maintaining the operational efficiencies they were now achieving in the new warehouse.”

Working closely together with Simpson Packaging, all options were considered, including VNA, but the number of different loads and pallet sizes would have been far too restrictive, so the recommendation was made to replace the Reach Trucks with three Aisle-Master Articulated Forklift Trucks. Forkway have been Aisle- Master/Combilift Regional Dealer of the Year for the past 3 years, and with the knowledge and experience gained, were able to offer Simpson Packaging valuable advice on layouts and aisle widths.

The result: three high specification Aisle-Master 20SHE Articulated Forklifts were supplied, complete with 9450mm triple masts and FleetSafe telematics, which enable Simpson Packaging to tailor the trucks parameters to suit the application as well as monitoring the performance of the trucks and operator. Thanks to the innovative steering system of the Aisle-Master, and taking into consideration the various pallets to be accommodated, a second phase racking installation created new aisles which were reduced from 4000mm right down to 1880mm, giving Simpson Packaging an increase of over 1200 pallet locations!

“The new Aisle-Master trucks really have made a significant difference, according to Simpson Packaging, Partner, Andrew Simpson. “When we first moved into the new facility in October 2016, we were quietly confident that Reach Trucks were the right option for us, but the excellent growth we have enjoyed since the move forced us to re-evaluate the whole warehouse operation. It’s fair to say that the Aisle- Master’s took a little getting used to at first, with them having different drive characteristics to Reach Trucks, but with the right training and support from Forkway, our forklift drivers were soon up to speed. The fact that they can operate outdoors on loading duties has also been an added advantage.”

Compared to the old warehouse, Simpson Packaging have seen a massive increase in efficiency by being able to stack single deep and having the luxury of deciding which products go where. Damage to product and equipment was another huge problem in the old warehouse, as was health and safety issues, so by creating a better working environment and giving their team the correct tools for the job, this is no longer an issue.

Also in operation from Forkway is a refurbished electric forklift fitted with extending forks and a powered pallet truck which operates on the dock leveller, and for general pallet movements.

We were a little concerned at first when Richard suggested that we reduced the aisle widths by halve, as that meant the whole warehouse operation would rely on the uptime of the Aisle-Masters, but we have had an excellent working relationship with the Forkway Group for over 15 years and the levels of service and first fix rates have been first class, commented Simpson Packing, Partner, Oliver Dawes.